Krion Consulting is a global leader in digital transformation, specializing in high-end BIM, VDC, and Digital Twin solutions. By bridging the gap between physical infrastructure and digital intelligence, Krion empowers AEC (Architecture, Engineering, and Construction) and manufacturing sectors to achieve unprecedented efficiency. Through their flagship Krion 6D platform and AI-driven Krion6i engine, they provide actionable insights that reduce risks and optimize costs. With a presence spanning India, Singapore, and the USA, Krion is redefining Industry 5.0 through human-centric automation and data-driven foresight. In an exclusive interview with CMR, Ramasamy Balasubramanian, Managing Director of Krion Consulting, speaks on the trends and their expansion plans.

Q1. What are the key differentiators of the Krion 6D Digital Twin platform, and how does it guarantee a 15% reduction in cost overruns for construction clients?

“Krion 6D is not just a digital twin—it is a decision intelligence platform. By combining coordinated project data with AI-driven foresight through Krion6i, we help clients prevent cost overruns before they occur.”

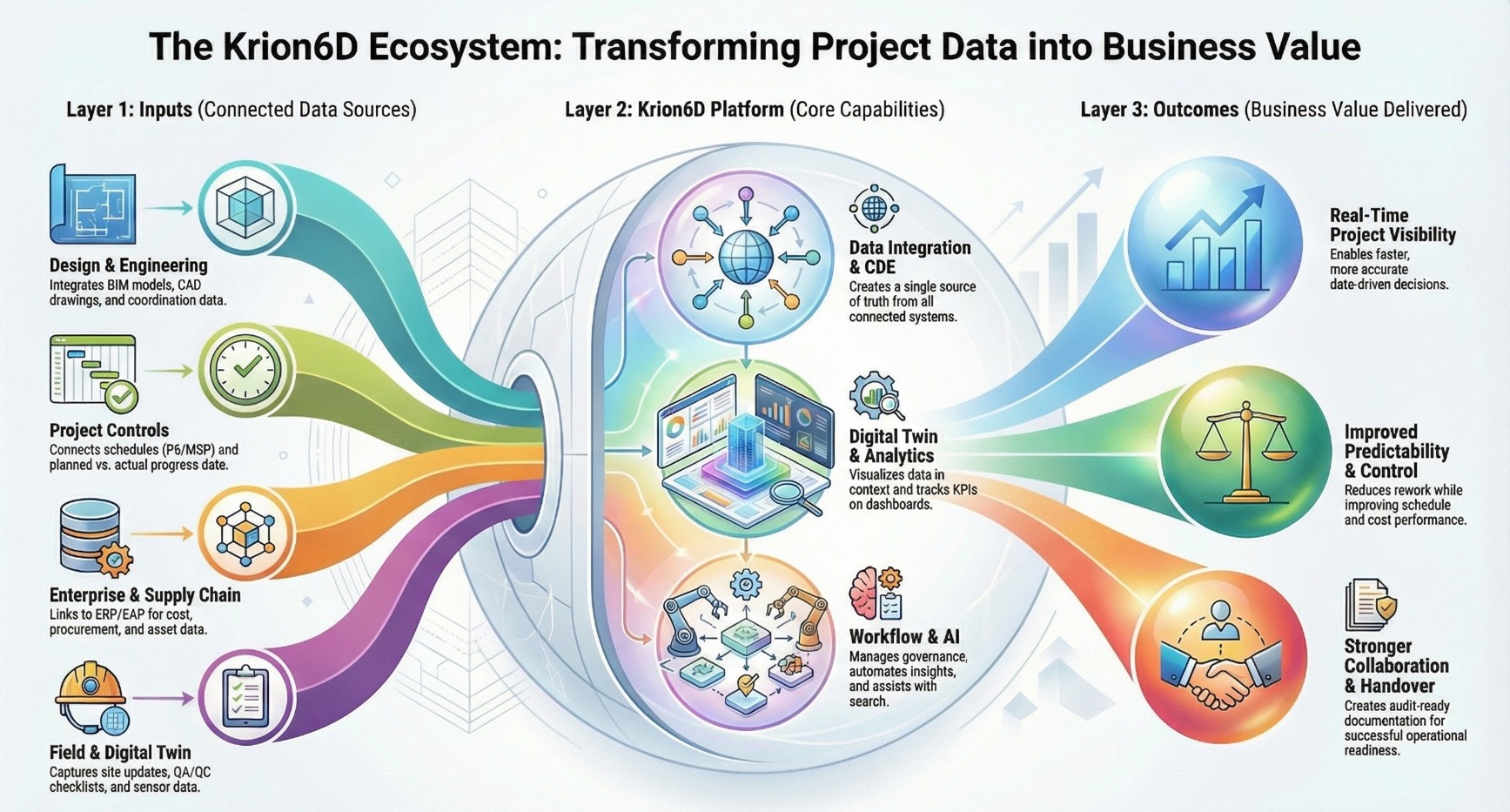

Krion 6D stands out by combining a true Common Data Environment with a live digital twin that links BIM, drawings, schedules, costs, RFIs, and changes into a single, traceable system. Unlike passive CDEs, it provides real-time context and impact visibility for every decision. This foundation is enhanced by Krion6i, Krion’s AI intelligence layer, which sits above the digital twin to continuously analyze project data and surface early warnings, insights, and recommendations.

The platform delivers a 15% reduction in cost overruns by combining coordinated project data with AI-driven risk detection, automated quantification, faster RFI and change resolution, and prescriptive decision support. Krion6i’s objective is to shift teams from reactive issue management to proactive, insight-led control by predicting cost and schedule risks before they escalate.

Q2. How does Krion Consulting integrate advanced technologies like AI, IoT, and AR/VR/MR into its automation solutions to prepare manufacturing clients for Industry 5.0?

“Our digital twin–centric approach brings AI, 4D/5D intelligence, IoT, and immersive technologies together—so humans and intelligent systems can collaborate effectively, not compete.”

Krion Consulting integrates AI, IoT, and AR/VR/MR through a digital twin–centric automation framework aligned with Industry 5.0. Digital twins form the core, enriched with 4D (time) and 5D (cost) intelligence to link schedules, resources, and financial outcomes directly with physical and virtual assets. Krion6i, the AI intelligence layer, analyzes model, image, and site data to deliver predictive insights and decision support, while IoT feeds real-time operational data into the twin for continuous monitoring and optimization.

AR/VR/MR technologies, powered by Krion6i, enable AI-assisted quality and inspection workflows, including AR-based detection of construction issues, snags, and deviations by comparing site conditions against the digital twin. These capabilities support immersive reviews, guided execution, and faster quality closure—allowing humans and intelligent systems to collaborate more effectively while improving productivity, predictability, and sustainability.

Q3. Given your diverse client base (Aerospace to EPC), do your digital transformation methodologies change significantly, or do you apply a standardized approach across all sectors?

“We standardize the foundation through ISO 19650 and global BIM standards, while customizing execution for sectors like buildings, infrastructure, defence, and EPC.”

Krion follows a standardized digital transformation foundation built on ISO 19650 principles and global BIM standards, covering data structuring, information management, digital twins, and automation. This ensures consistency, governance, and interoperability across projects and geographies.

At the same time, the methodology is highly adaptable and customizable to regional regulations and sector-specific needs, including Buildings, Infrastructure (roads, railways), Defence infrastructure, and EPC projects. Domain-specific workflows, data models, compliance requirements, and KPIs are configured to suit each sector, enabling both standardization at scale and practical relevance on the ground.

Q4. Why were Singapore and the USA chosen as the next global expansion hubs, and what primary market opportunities do you foresee in those regions?

“Singapore and the USA represent the convergence of standards, technology, and AI-led transformation—making them ideal launchpads for scaling intelligent digital twin solutions globally.”

Singapore and the USA were chosen for their leadership in high-technology adoption, global standards compliance, and accelerated AI-driven transformation. Singapore serves as a hub for Southeast Asia’s infrastructure and advanced manufacturing growth, with strong government-led adoption of digital twins, BIM standards, smart infrastructure, and AI initiatives.

The USA offers the world’s largest market for construction technology, digital twins, and AI-enabled platforms, supported by mature industry standards, innovation ecosystems, and a strong push toward automation and intelligence at scale. Together, these regions provide the ideal environment for scaling Krion’s AI-driven digital twin solutions globally.

Q5. Which specific service offerings—such as Krion 6D or BIM/VDC—will you prioritize to establish initial market penetration in the USA and Singapore?

“From secure on‑premise digital twins for government and utilities to AI‑driven, repeatable delivery models for large contractors, our focus is on scale, security, and speed to value.”

Krion will prioritize Krion 6D Digital Twin deployments with on‑premises, high‑security architectures for data‑sensitive customers such as defence, government agencies, utilities, and critical infrastructure owners. These offerings address stringent security, compliance, and data sovereignty requirements.

For large enterprises, Krion will focus on custom digital twin and BIM/VDC solutions integrated with existing enterprise systems—including ERP, asset management, and project controls—deployed within customer data centers. In parallel, AI‑driven, repeatable digital twin and automation solutions will be rolled out for large general contractors to enable scalable, standardized project delivery across portfolios.

Q6. What is your strategy for recruiting, training, and scaling local talent in the USA and Singapore to maintain the high quality of your specialized solutions?

“Our hybrid model combines local partners and customer proximity with world‑class, cost‑efficient AI expertise from India—ensuring both scale and specialization without compromise.”

Krion’s approach combines leveraging existing local BIM and CDE partners with targeted talent development to ensure a strong local presence and close customer engagement. These partnerships provide immediate market access, domain familiarity, and on-ground support while maintaining delivery speed and quality.

This is complemented by access to highly skilled, cost-efficient AI and digital engineering expertise based in India, forming a strong global delivery backbone. Krion follows a hybrid operating model—offering consulting-led engagement, structured handholding, and deep expertise through a blend of local teams and remote specialists. Continuous upskilling, knowledge transfer, and mentoring ensure customers and partners are progressively enabled, while maintaining consistent global delivery standards as operations scale.