In today’s hyper-competitive world, efficiency is absolutely key to success. More so, when it comes to automotive industry. With unexpected fluctuations in external conditions such as economic downturn or vehicle failure, profit can easily turn into loss. Enterprises can ill-afford to allocate costly resources and lose time on unwarranted and unspecified maintenance. The rise of Internet of Things (IoT) is playing a key role in reducing unexpected and unplanned downtime, and in doing so, making a fundamental business shift from ‘repair and replace’ to ‘predict and prevent’. It focuses on figuring out when an asset should be maintained, the key initiatives to be performed, taking actual state of equipment in mind. In doing so, enterprises will be able to avoid costly equipment downtime by performing maintenance routines and thereby predicting and preventing failures.

In today’s hyper-competitive world, efficiency is absolutely key to success. More so, when it comes to automotive industry. With unexpected fluctuations in external conditions such as economic downturn or vehicle failure, profit can easily turn into loss. Enterprises can ill-afford to allocate costly resources and lose time on unwarranted and unspecified maintenance. The rise of Internet of Things (IoT) is playing a key role in reducing unexpected and unplanned downtime, and in doing so, making a fundamental business shift from ‘repair and replace’ to ‘predict and prevent’. It focuses on figuring out when an asset should be maintained, the key initiatives to be performed, taking actual state of equipment in mind. In doing so, enterprises will be able to avoid costly equipment downtime by performing maintenance routines and thereby predicting and preventing failures.

As such, enterprises will be able to leverage IoT to build business competitiveness and profitable.

IoT-based automotive predictive maintenance is on the rise driven, among others, by the following key trends:

- Rising maintenance cost of vehicles, leading to increased preference by vehicle owners to reduce these costs and have more control on the maintenance of their vehicles

- Stringent vehicle fuel efficiency and safety norms, being adopted relentlessly, especially in the developed markets.

- Increased demand from the vehicle/fleet owners, to reduce the vehicle downtime and increase the operational reliability of their vehicles.

- Decreasing cost of sensors, embedded chips, Artificial Intelligence Systems, cloud computing, machine learning and embedded software, making IoT in predictive maintenance, attractive to the potential vehicle/fleet owners.

IoT-based automotive predictive maintenance is classified into following three segments:

- IoT based predictive maintenance hardware: In this segment, IoT sensors are the key components. IoT sensors are used to monitor a vehicle with respect to various parameters like vibrations, volume of load being carried, fuel consumption, fuel and oil leakages, wear and tear of a particular vehicle part, tire pressure, total distance travelled by that vehicle in a day etc. on the real time basis. The data collected by these sensors, is analyzed, through a business intelligent platform and stored in a secure cloud environment. The IoT sensors are connected to business intelligence platform and cloud environment, through wired, LAN (Local Area Network), Wi-Fi and cellular networks. These network components can also be grouped under IoT predictive maintenance hardware. Embedded chips power these IoT sensors, so they can be called as engine of an IoT based predictive maintenance system. Other IoT based predictive hardware include IoT enabled valves to measure the specific flow of fuel, IoT enabled actuators to precisely control the movement of these valves, alarms to signal the need for the maintenance or replacement of a particular part, telemetry systems to pinpoint the exact location of the vehicle, Programmable Logic Controls (PLCs) to run and control the overall IoT based predictive maintenance system and information displays, to present the collected and analyzed data, to the end user.

- IoT based predictive maintenance software: We can see that all the data, collected by IoT based predictive maintenance system is analyzed by a business intelligence platform, powered by Artificial Intelligence, using machine learning based algorithms, on the real time basis. This analyzed data is then stored in a secure cloud environment and presented, to the end user, in easily understandable way. This combination of business intelligence platform and secured cloud environment, along with the associated Artificial Intelligence capabilities and machine learning based algorithms constitutes the software part of an IoT based predictive maintenance system. Software is often termed as brains behind an IoT based predictive maintenance system, as it enables the most critical function of collecting, analyzing and presenting the data, before the end user, in an IoT based predictive maintenance system.

- IoT based predictive maintenance services: Today many companies and some startups in IoT based predictive maintenance industry, are offering both IoT based predictive maintenance hardware and software, as a single package, to the fleet owners, resulting in some real cost savings for the fleet owners. They are also offering data processing and data storage services to their clients. Newer on demand IoT based predictive maintenance services are also being increasingly offered, wherein a client may not invest upfront in an IoT based predictive maintenance, but utilize it, as and when needed, by leasing it from a IoT based predictive maintenance service provider, through a fixed term contract, by paying a subscription fee to the service provider. All these offerings are grouped under the segment of IoT based predictive maintenance services.

Barriers for IoT-based automotive predictive maintenance

While there is lot of potential, there are some barriers that continue to impede the growth of IoT in automotive predictive maintenance industry. These include:

- Hardware Compatibility Issues: Data capturing majorly occurs through various sensors, PLCs, etc., which are connected to IoT gateways to collect & transmit data to the cloud. Vehicle manufacturers need to identify both the hardware and software, which are compatible with each other, keeping in view their business and operational goals, which is a very complex and time consuming process. This adds to the cost of the final vehicle, making such vehicles less attractive, for the potential customers.

- Data Connectivity Issues: Some data connectivity challenges include how IoT devices talk to the gateway & the Cloud and what data format do they generate. Most IoT gateways available are compatible with GPRS and Wi-Fi/LAN, but legacy devices depend on PLCs, telemetry systems and RTUs to generate data. A suitable edge layer that translates transport and data format protocols to send data to the IoT platform, thus becomes essential. This again increases the price of IoT enabled vehicles, decreasing their sales potential.

- Incorrect Data Capture Issues: Once an IoT enabled vehicle is up and running, data capturing issues can occur, due to some unwanted incident or the inability of the software to handle certain discrepancies in run time, leading to inaccurate data recorded and incorrect analysis of that data, which hampers the ability of making correct decisions. This also presents a dilemma, before vehicle manufacturers, whether to incorporate IoT predictive maintenance systems, into their vehicles, or not.

- Data Security issues: IoT based predictive maintenance systems, are prone to ransomware attacks. Since customers today are hypersensitive to the safety of their data, secure Internet connectivity, coupled with an advanced cybersecurity platform and a robust data governance framework, become prerequisites for a safe IoT based predictive maintenance system. This again tends to increase of IoT based predictive maintenance systems, again putting a question mark, on their incorporation in the vehicles, by the vehicle manufacturers, citing cost issues and decreased sales potential of IoT enabled vehicles.

- Different Government Data Regulatory policies, in different markets, lead to restrictions on what kind of sensitive data can be transferred or shared with third party applications.

- A proper IT Analytics system is required to analyze the vast amounts of data that is being captured, from the vehicle, on a real time basis, resulting in the need of IT and Analytics experts, which again increases the upfront costs in the implementation of IoT based predictive automotive maintenance systems.

Major OEMs dominating the IoT predictive vehicle maintenance market include Robert Bosch GmbH, Intel Corp., Rockwell Automation Inc., Samsung Electronics Ltd through their acquisition of Harman International Industries Inc., Delphi Technologies, Siemens AG and Teletrac Navman, in the hardware components space.

When it comes to software in IoT predictive vehicle maintenance market, key players include IBM, Microsoft, SAP, Cloudera and IMS (part of Trak Global Group), dominating the global market.

In IoT predictive vehicle maintenance services market, key players are Pega Systems, AVEVA Predictive Analytics, IBM Corporation, L&T Infotech Ltd., Siemens AG, Infinite Uptime India Pvt Ltd and Embitel.

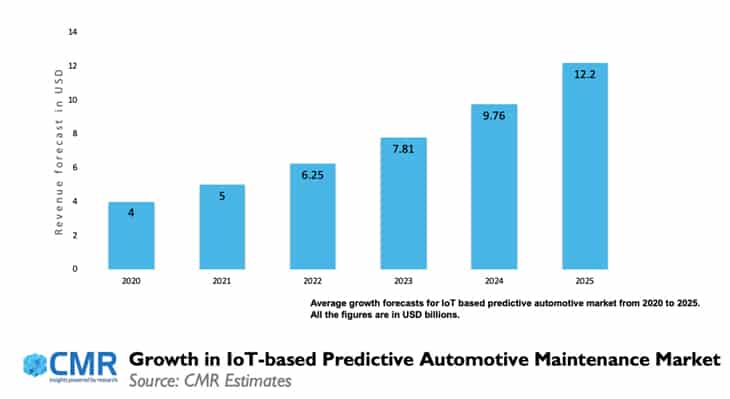

Our early estimates point that the IoT in automotive predictive maintenance market will potentially grow at a CAGR of 25%, from 2021 to 2025. North America was the largest market for IoT predictive vehicle maintenance industry and Asia Pacific was the fastest growing market, in the world.

Conclusion

Conclusion

IoT-based automotive predictive maintenance is one of the most rapidly growing applications of IoT, worldwide. Real world test scenarios have clearly shown that incorporating IoT-based automotive predictive maintenance systems in their fleets, have led to the cost savings estimated in the range of 25% to 25%, when compared with fleets without IoT-based automotive predictive maintenance systems. In some cases, fleet owners have reported Return of Investment (RoI) as high as 500%, after implementation of IoT-based automotive predictive maintenance systems, in their fleets. This has led to massive improvements in operational reliability of their fleets, resulting in considerable cost savings for them. Thus, we can safely conclude that IoT-based automotive predictive maintenance industry will continue to grow, in the foreseeable future.

Conclusion

Conclusion